The APC Solenoid Valve

![]()

The solenoid valve regulates the charge air pressure. It

is connected in the line from the turbo to the waste gate. The inlet port of the solenoid

valve contains a fixed diameter restriction. The waste gate actuator is connected down

stream of this restriction. The diameter of the outlet port of the solenoid is governed by

the frequency and duty cycle that the valve is oscillating at. When energized,

the solenoid valve oscillates between the open and closed positions at a fixed frequency

of 12hz (12 times per second). If the boost pressure rises above 6 psi (.4bar), the

pulse width of the valve will change. The pulse width is the relationship between

the amount of time that the solenoid is open and the amount of time that the solenoid is

closed within that 1/12 of a second cycle.

The solenoid valve regulates the charge air pressure. It

is connected in the line from the turbo to the waste gate. The inlet port of the solenoid

valve contains a fixed diameter restriction. The waste gate actuator is connected down

stream of this restriction. The diameter of the outlet port of the solenoid is governed by

the frequency and duty cycle that the valve is oscillating at. When energized,

the solenoid valve oscillates between the open and closed positions at a fixed frequency

of 12hz (12 times per second). If the boost pressure rises above 6 psi (.4bar), the

pulse width of the valve will change. The pulse width is the relationship between

the amount of time that the solenoid is open and the amount of time that the solenoid is

closed within that 1/12 of a second cycle.

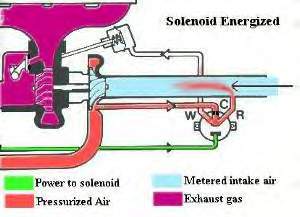

When the valve

is fully open (energized), pressure is evacuated through the "R" port, to

the inlet side of the compressor. The restriction in port "C" is so narrow in

comparison with the valve opening that there is a total pressure drop in the small

quantity of air flowing through the restriction, thus preventing the waste gate from

actuating.

When the valve

is fully open (energized), pressure is evacuated through the "R" port, to

the inlet side of the compressor. The restriction in port "C" is so narrow in

comparison with the valve opening that there is a total pressure drop in the small

quantity of air flowing through the restriction, thus preventing the waste gate from

actuating.

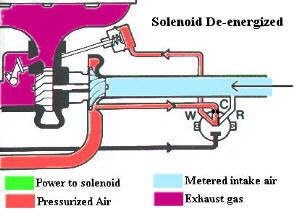

When the

solenoid valve is fully closed (de-energized), the waste gate actuator is connected

to the full pressure present from the compressed charge air. Since the R port is closed

off, the pressure to the waste gate is no longer allowed to dump to the inlet side of the

turbo compressor. Therefore, the waste gate is allowed to open and the boost is reduced to

the basic setting. The "Basic boost setting" is that which the waste gate would

normally open at without any intervention from the APC.

When the

solenoid valve is fully closed (de-energized), the waste gate actuator is connected

to the full pressure present from the compressed charge air. Since the R port is closed

off, the pressure to the waste gate is no longer allowed to dump to the inlet side of the

turbo compressor. Therefore, the waste gate is allowed to open and the boost is reduced to

the basic setting. The "Basic boost setting" is that which the waste gate would

normally open at without any intervention from the APC.

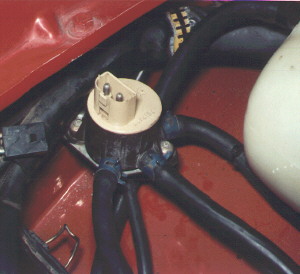

The routing of the

solenoid hoses is quite simple. As you're looking at the solenoid with the ports facing

you, The port on the left goes to the intake upstream of the turbo and downstream of the

fuel metering device (air mass meter, or the air flow plate). On my 740, there is a very

expensive formed rubber hose that goes from the air mass meter to the intake of the turbo.

There was no good way to tap into this hose, but I was able to build a T fitting (See Photos) in the line from the crank case

ventilation to this hose. The center port with the restriction in it goes to the fitting

on the side of the turbine housing of the turbo. On my turbo, there was a 90 degree elbow

on it which I rotated to the necessary position for hookup to the solenoid. The port on

the right goes to the waste gate actuator.

The routing of the

solenoid hoses is quite simple. As you're looking at the solenoid with the ports facing

you, The port on the left goes to the intake upstream of the turbo and downstream of the

fuel metering device (air mass meter, or the air flow plate). On my 740, there is a very

expensive formed rubber hose that goes from the air mass meter to the intake of the turbo.

There was no good way to tap into this hose, but I was able to build a T fitting (See Photos) in the line from the crank case

ventilation to this hose. The center port with the restriction in it goes to the fitting

on the side of the turbine housing of the turbo. On my turbo, there was a 90 degree elbow

on it which I rotated to the necessary position for hookup to the solenoid. The port on

the right goes to the waste gate actuator.

This is a picture of the

solenoid valve mounted on the inner fender in front of the coolant reservoir, and behind

the air filter housing..

This is a picture of the

solenoid valve mounted on the inner fender in front of the coolant reservoir, and behind

the air filter housing..